A Case of Serious Maintenance Lapse, Lack of Regulatory Oversight, and OEM’s Negligence

Brief Description of the Occurrence

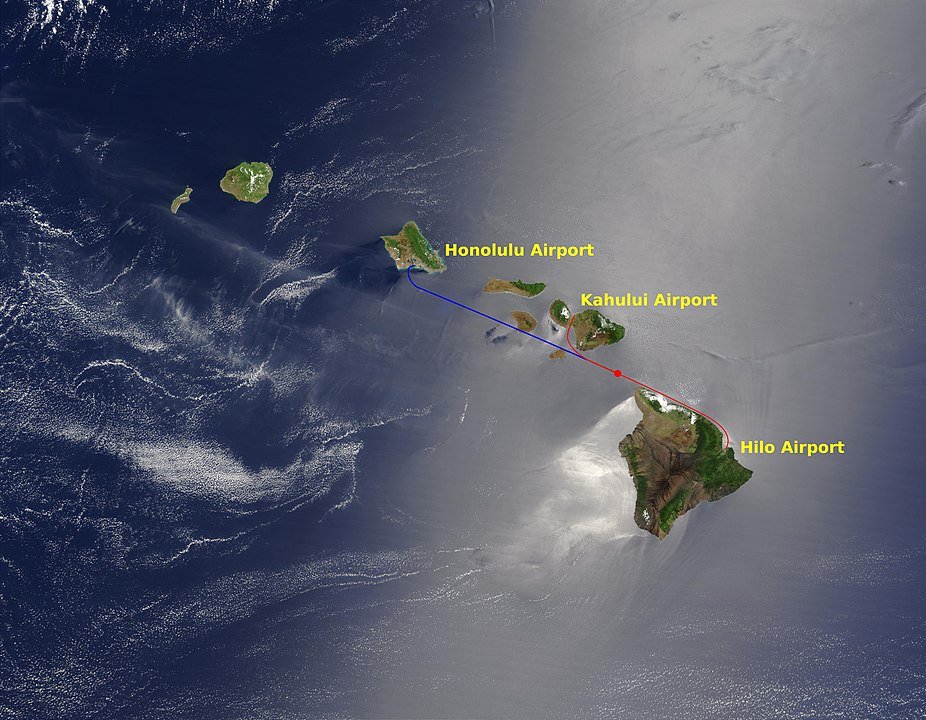

On April 28, 1988, a Boeing 737-297 Aloha Airlines Flight 243 (IATA: AQ243, ICAO: AAH243) was scheduled between the Hilo and Honolulu islands in Hawaii. During the flight, the aircraft experienced extensive cabin damage just behind the cockpit area after a sudden decompression. The aircraft somehow managed to survive miraculously and landed safely at Kahului Airport, Maui. One of the flight attendants, Clarabelle Lansing, got sucked out of the airplane due to severe decompression. During all this mayhem, 65 passengers and members of the cabin crew received major and minor injuries.

Investigation Agency

The investigation of the accident was conducted by the National Transport Safety Board (NTSB), USA.

Details of the Investigation

April 28, 1988, was a routine flying day for Aloha Airlines. Flight 243 was a domestic flight scheduled between the Hilo and Honolulu islands. The flight departed from Hilo International Airport at 13:25 HST. There were six crew members and 89 passengers on board. The aircraft under discussion had already completed three round-trip flights from Honolulu to Hilo, Maui, and Kauai earlier. All the flights were uneventful.

What Happened Up there?

The take-off was uneventful as well. Flight 243 ascended to a normal flight altitude of 24,000 feet (7,300 m) after the take-off. At about 13:48, while flying about 23 nautical miles (43 km; 26 mi), south-southeast of Kahului on the island of Maui, a small section on the left side of the cabin roof got ruptured and flew away.

The Worst was about to happen!

Sudden rupture of the cabin top created severe decompression which caused the aircraft to roll to the left and right. As a result of this damage, the cockpit door had also broken away. According to the captain, he could actually see the blue sky in the area where the first-class ceiling had been prior to this serious incident. In reality, the intensive decompression had torn off a large section of the roof, consisting of the entire top half of the aircraft skin running from just behind the cockpit to the fore-wing area. Later investigation by NTSB concluded that the length of the missing aircraft skin was about 18.5 feet (5.6 m). Fortunately, the fuselage did not disintegrate completely. It was a terrible situation to experience!

Decompression

Decompression is the loss of excessive controlled pressure, also known as depressurization. The speed of pressure loss is predominantly used to characterize the decompression process. One of them is explosive decompression.

Fatality

There was one fatality in this accident. A 58-year-old flight attendant Clarabelle Lansing, nickname ‘C.B.’ She was a senior flight attendant on board. Unfortunately, she was standing near the fifth row from the cockpit. This was the affected area at the time of the occurrence. Unfortunately, she got scooped out of the aircraft due to the sudden rupture of the roof skin and the subsequent decompression phenomena. Her body was never found. Eight other people suffered serious injuries.

They finally made it!

The aircraft controls had also been affected by the sudden pullover of a major akin chunk from the front portion of the fuselage. First Officer Tompkins was the pilot flying at the time of the incident; Captain Schornstheimer took over controls and performed an immediate emergency descent. The crew followed the standard procedures. They declared an emergency and diverted the aircraft to the nearest Kahului Airport for an emergency landing. During the approach to the airport, one of the plane’s engines failed, and the flight crew was also unsure if the nose gear was lowered correctly. Somehow, they managed to land thirteen minutes after the incident. Upon landing, the aircraft’s emergency evacuation slides were deployed, and the passengers quickly evacuated from the aircraft. The pilot and first officer were heroes of the moment. Their professionalism saved the precious lives of the passengers.

Prime Cause of the Occurrence

NTSB concluded the investigation by attributing Metal Fatigue and Crevice Corrosion (a type of corrosion that seeps into the crevices of the metal structure). The prime cause of metal fatigue was the reason that an aircraft structure is designed for a certain number of flight cycles (takeoffs and landings). The mishap aircraft had accumulated twice the number of flight cycles it was designed for, at the time of the accident. The same can be related to the fact that the mishap aircraft had done three short-haul return trips within the same day, and it was the fourth one in a row.

Point of Crack Initiation

Compounding the frequency of flights on daily basis can actually help relate the metal fatigue phenomena. Unlike humans, metals also behave with operating conditions and gave up after a certain period of time. However, this does not occur in a few days. It takes years for metal to lose its strength but the frequency of exposure to loading conditions may shorten its life like the one that happened in the case of Aloha Flight 243. The cracks had already been initiated in the lap joints of the fuselage prior to the accident. The second cause was valid due to the fact that the aircraft had been operating under sea conditions for all these years therefore, it was prone to a highly corrosive environment.

Analysis

- The investigation determined that the quality of inspection and maintenance programs of Aloha Airline was deficient. They also discovered that the fuselage examinations used to be scheduled during the night. Due to poor lighting conditions, it was difficult to carry out an adequate inspection of the aircraft’s outer skin. This anomaly directly contributes to the lapses in the maintenance program of the airline. The maintenance team failed to identify those multiple cracks on the fuselage prior to the accident or it could be negligence on the part of the airline if the maintenance team intentionally overlooked it to drag it further for some major structural inspection.

- The regulatory body, Federal Aviation Authority (FAA) was also blamed for its lack of oversight in conducting a proper Airworthiness Directive 87-21-08 inspection of all the lap joints proposed by Boeing Alert Service Bulletin SB 737-53A1039. Their slackness made the airline management more callous in dealing with the problem on time.

- Another notable discrepancy found during the investigation was an incomplete terminating action at the end of OEM (Boeing) after the discovery of early production difficulties in the B-737 cold bond lap joint which resulted in low bond durability, corrosion, and premature fatigue cracking. Moreover, FAA also did not enquire Boeing to remove this anomaly to complete the terminating action. Again, a serious issue at the ends of the regulator and manufacturer.

Lessons Learnt

- In view of the grey areas found in the investigation, there are lessons to be learned.

- Metal fatigue phenomena are real. Therefore, a comprehensive monitoring system must be in place to keep a check on mental behavior.

- The maintenance teams must be very cautious in terms of structural issues. Especially, for those airports that are located at the sea as corrosion factor is very common and of high grade as compared to the land and hilly/mountainous areas.

- The regulators have a critical role to play in ensuring the implementation of the State Safety Program (SSP). Their callousness gives relaxation to the operators in implementing the Safety standards. They should also keep a vigilant eye on the manufacturers for their design deficiencies and make sure to close the unresolved loops.

- Last but not the least, the OEM should not always try to save the cost at the stake of millions of lives traveling in their aircraft. It actually hurt the trust of the customer which ultimately leads to heavy losses for the company. The case of Boeing 737 MAX is a glaring example of such negligent behavior on the part of the OEM. The outcome has been witnessed by the world. The aircraft is finally making its way back to the market after a lapse of almost two years on the ground; followed by a comprehensive recertification process.

Written by guest writer, Faisal Bashir